Designed to operate in pharmaceutical production, meets the highest hygienic standards Manufactured in accordance with cGMP, PED, ASME

P-line

Designed to operate in pharmaceutical production, meets the highest hygienic standards Manufactured in accordance with cGMP, PED, ASME

Spiral tubes ensure turbulent rotational flow, which doubles the heat exchange coefficient. Low pressure drops and lack of dead zones

High efficiency Effective energy recovery High level of hygiene Made of stainless materials

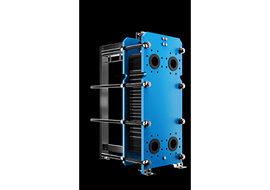

High heat performance Compatible with all heat sources Dismountable design – allows for cleaning and extension, if necessary

High thermal performance thanks to innovative heating plate corrugations pattern Technical solutions facilitating the exchanger installation and operation

Greater capacity due to the use of a corrugated heating plate that creates an additional channel. Lower water pressure drops – secondary side.

Materially homogeneous design made entirely of stainless materials High hygienic level Long-term life span

Double wall system – helps to prevent potential mixing of working media Quick detection of internal leakage – leading the leakage outside

Effective cooling medium evaporation or condensation thanks to the specially formed channels Dynamic boiling medium distribution system (RDS)

Turbulent flow – thanks to the special corrugation pattern of the heating plates Airtight design – permanent connection of the plates during the vacuum brazing process, using the copper or stainless LUNATM brazing.